Industrial Storage Solution & Material Handling Equipment

Industrial Storage Solutions

1. Pallet Racking Systems / Adjustable Shelving / Storage Racks

Pallet Racking System is the best solution for storing medium and heavy material. With a high-density storage capacity, all the stock in pallet racking is exposed to direct access. You can use it to store boxes, Gunny bags or loose goods. You can also use plastic / wooden / MS pallets for material storage. Being a highly versatile system, it can bear various types of loads. Based on your product requirements, you can choose any suitable frame type. Pallet racking includes Vertical Column beams, shelves, and a combination of it. The beams are horizontal, adjustable and are connected to the upright column. The box beams are what support the shelves and loads. It is an enhanced version of Slotted Angle Shelving with longer spans, more depths and higher load capacities.

2.Double Deep Racking Systems

It helps to use maximum space than pallet racking system. Where you can keep two pallets back-to-back. It gives batter advantages of cost cutting by using maximum space with minimum cost. It is a storage system that is halfway between adjustable pallet racking systems and compact storage systems. In this system, the pallets are stored at two depths, thus achieving higher storage density, while access to the pallets remains simple and relatively quick. Double deep Racking System is a best solution for storing medium and heavy material. With a high-density storage capacity, it is almost the same as a pallet racking system.

In the pallet racking system, there is one rack and in double deep racking are two racks front – back. So, its usage maximum passage of warehouse to store material. You can use it to store boxes, Gunny bags on pallets. You can also use plastic / wooden / MS pallets for material storage. Being a highly versatile system, it can bear various types of loads. Based on your product requirements, you can choose any suitable frame type. Double deep racking includes Vertical Column beams, shelves, and a combination of it. The beams are horizontal, adjustable and are connected to the upright column. The box beams are what support the shelves and loads. The beams are the most important part in this system as they provide rigidity to the whole structure. It is an enhanced version of Slotted Angle Shelving with longer spans, more depths and higher load capacities. It helps to use maximum space than pallet racking system. Where you can keep two pallets back-to-back. It gives batter advantages of cost cutting by using maximum space with minimum cost.

Long Span Racking System is a best solution for storing medium and heavy material. With a high-density storage capacity, all the stock in Long Span racking is exposed to direct access. You can use it to store, boxes, Gunny bags or loose goods. Being a highly versatile system, it can bear various types of loads. Based on your product requirements, you can choose any suitable frame type. Long Span racking includes a Vertical Column beam, shelves, and a combination of it.Ideal for storing bulky or long goods, this storage system comes in a wide array of height, width, and depth to adjust to different space configurations. It is an enhanced version of Slotted Angle Shelving with longer spans, more depths and higher load capacities.

3. Light Duty Long Span Racking

Long Span Shelving is also known as Light Duty Long Span Storage Racks, Light Duty Long Span Shelving, Light Duty Long Span Storage Shelving, Light Duty Long Span Garage Shelving, Light Duty Long Span Warehouse Shelving, Light Duty Long Span Metal Shelving and many other variations. In the storage industry it refers to shelving units that span a great length or have the capacity to be extended to great lengths.

4. Slotted Angle Racking

Products covered under this category are also known as Adjustable Racks, Iron Racks, Light Duty Racks, MS (Mild Steel) Angle Racks, Storage Racks, Clothes Racks, Mall Racks, Shelving Racks, Steel Racks, Angle Racks, Heavy Duty Racks etc. We make these cost-effective racks as per customer requirement. It includes a Slotted angle, shelve / panel, hardware, and other accessories. These are powder coated as well as we use GI Panel. Our Slotted angle (also sometimes referred to as slotted angle iron) is a system of reusable metal strips used to construct shelving, frames, work benches, equipment stands and other structures.

Our Slotted Angle Rack is the one of the most Quality and low-cost storage solution for light goods. The panels can be totally dismantled and reassembled easily with the use of just manual spanners. This rack is highly durable, strong, and adjustable and comes in various lengths, heights, and combinations. Slotted angle rack is probably the simplest storage solution ever made for manual storage of light goods. Its height and length can be easily adjustable. With around 100 – 200 kg per level of load bearing capacity, slotted angle racks are ideal for those looking for simple and economical storage systems. Using the multiple bolts and combinations, these racks can be adjusted manually for any goods of any kind of size, length, and height.Slotted angle Racking System contains of slotted angles and shelves / panel that are bolted together. Companies, stores, warehouses, offices, shops etc. use this type of storage for light and medium duty goods. You can also find these racks in libraries, malls.

5. Multi-Tier Racking

Multi-Tier Racking consists of Mezzanine Racking Systems & Mezzanine Racks.

It can be one layer, two or many layers. It allows to use maximum space, height with manual operation. These are used for light duty and medium duty storage. Our Multi-tier Racking designed for warehouses with limited floor areas but available height, are manual storage solutions that maximize warehouse space. They offer an optimum use of height with the creation of different levels of manual loading aisles at different heights accessible by stairs.

A multi-tier shelving is a multi-floor shelving that eliminates the need of a structural floor. It increases floor space and optimizes the storage capacity by utilizing the height of the building in concern. This shelving system provides a perfect solution to limited floor space. In normal circumstances, the spaces which are useless are specifically used in this case, thereby increased the storage capacity. A multi-tier racking system increase the storage capacity of the shelving in multi-folds by increasing the no of floor or access levels across the system. This is achieved by adding catwalk levels between racks which allow you to access all the shelving levels very ergonomically. These systems reduce the footprint area and increase the storage capacity of the shelving. A perfect storage and warehousing solution for the areas which have high roof. It also has the ability to accommodate various other types of shelving€™s if need be. A perfect solution for automobile, apparel, pharmaceutical types of industries. Multi-tier shelving is scalable and pretty much affordable. Adding extension bays and creating more space is also a strong advantage with multi-tier shelving. The structure designed by us, in this case, is very sturdy and can handle day to day rigors of warehousing well. Enhancements that can be done with multi-tier shelving are many. Our storage systems can easily be calibrated with adjustable dividers, shelf bin fronts, provisions for garment hanging, plastic drawers, cupboard doors, filing cradles, and many more such attachments. In a nutshell, whatever the storage objective be, we have an efficient solution for it. It can be one layer, two or many layers. It allows to use maximum space, height with manual operation. These are used for light duty and medium duty storage.

6. Cold Storage Racking

Products such as Cold Room Racks, Pallet Racks, Double Deep Racks, Storage Racks for Cold Room, Frozen Racks, Selective Pallet Racks. Our Cold Storage Racks are Heavy Duty, High Quality. Maximum height utilizes, Maximum space utilized, easy to fit and move. The Cold Storage Racks are logistics solutions that facilitate the storage of products such as food and medicines at a controlled temperature in order to guarantee the conservation of their properties. These racks, usually made of stainless steel, are strong enough to function in cold and freezing environments. Additionally, they are tasked with maximizing warehouse space with two goals: on the one hand, to provide a high storage capacity, and on the other, to ensure energy efficiency, thanks to the proper distribution of cold among an increased number of pallets. Cold Storage Racks are Heavy Duty, High Quality, Maximum height utilizes, Maximum space utilized, easy to fit and move.

7. FIFO Racking / Racks / Rack Systems (First in First Out)

FIFO Racking / Racks / Rack Systems (First In First Out Racking), Cantilever Racking. As it applies to warehouse and distribution facilities, “FIFO System” means ensuring that the oldest pallets and products are shipped before the newer ones, thus properly rotating the stock. First in first out racking system is very effective storage system where you can maintain material batch wise. It is more use in Pharmaceutical, Food, Automobile Industries, Etc., sector where maintaining a product date wise is so important. So, this is very versatile racking system. It is very sturdy structure; we use nylon roller for it. We make c type track for roller fitting, they are adjustable. You can adjust that roller track as per your box size. Its use maximum space of warehouse, operation are manual. You have direct access to it.

8. Cantilever Racking

The Cantilever Racking is a storage system designed to store long, awkward, or bulky materials of virtually any length. Upright Columns connect to the base and have holes in which the cantilever arms are connected to creating the storage levels. Uprights can be used for single and double-sided units.

9. Drive in Racking Systems

Drive In Racks, Drive In Rack Systems. Our special Drive in Racking System is a high-density storage solution that maximizes available space and height in the warehouse by reducing the forklift operating aisles. It is the optimal and most common pallet storage system when you need to store homogeneous products with a large number of pallets of the same reference.

10. Radio Shuttle Storage Racking Systems

The Radio Shutle Storage Solutions’ Radio Shuttle Pallet Racking are Semi-Automatic or Fully Automatic Storage Solutions for handling goods inside channels similar to Drive-In systems. The system uses radio

shuttles to move independently within the rack itself, meaning Automatic Stacker (AS) Cranes can operate for other slots.

11. Mobile Racking Systems

Our Mobile Pallet Racking (AR Mobile) is a system where the pallet racks are placed on chassis or mobile bases guided through fixed tracks on the floor. Mobile pallet racking is a high-density storage system, providing simple access for conventional forklift pallets.

12. Compactor Racking

Compactor Racking consists of File Racks, File Storage Racks, Slotted Angle Compactor Racks, etc. Our Compactor (or Mobile Shelving unit and often referred to as a Compactus storage system) provides a very space efficient (high storage density) means for filing and storage. Simply put, it is shelving on wheels that runs along tracks.

Material Handling Equipments

1. Hand Pallet Truck

Hydraulic Trolleys, Pallet Jacks, Hydraulic Hand Pallet Trucks, HPT, Manual Trolleys, Hydraulic Material Movement Trolleys are one of the most versatile handling equipments suited for handling at ground level and transporting a load on a pallet.

Details:

Capacity – 3 / 5 ton

Fork length – 1150 / 1220 mm

Width oer fork – 550 / 685 mm

Wheel – Nylon / PU

Operation – Manual

2. Manual Pallet Stackers

Manual Stackers, Hydraulic Stackers, Manual Hydraulic Stackers, Pallet Lifters, Pallet Movers comes under stackers. Our Manual Pallet Stackers fulfill an important need for many warehouses and similar operations. … Designed to slide under pallets or other flat objects, these pallet stackers give you the ability to lift and position light to heavy loads and transport them over flat surfaces. Manual Hand Stackers are simple economic solution for storage and retrieval of pallets at vertical storage spaces at the least cost.

Details:

Capacity – 3 / 5 ton

Fork length – 1150 / 1220 mm

Width oer fork – 550 / 685

mm Wheel – Nylon / PU

Operation – Manual

3. Battery Operated Stacker

Providing a halfway house between the pallet truck and the forklift truck, semi electric tackers provide greater lifting potential than the pallet truck, whilst being a more economically viable alternative to the forklift. The Semi Electrical / Battery Operated Stacker is semi operated product that you can use for lifting material and moving to another place. It is very versatile product that you can use in different operation. This BOS stacker is use for boxes, bags, pallets, die, molds, any part of Machin, etc. BOS is cost effective product that can use in different operation, it takes less space for operation, fast and easy movement, low maintenance cost. BOS reduce the labor cost of loading and unloading activity. We have different type of model in it as per customer requirement. There are four operations in it – Up – down, reverse – forward, so up – down is automatic and other operation are manual, that’s why it is called semi electrical stacker.

Details:

Capacity – 3 / 5 ton

Fork length – 1150 / 1220 mm

Width oer fork – 550 / 685 mm

Wheel – Nylon / PU

Operation – Manual

4. Scissor Lift Table

Scissor Lift Tables, Manual Scissor Lift Tables, Automatic Scissor Lift Tables, Customized Scissor Lift Table. The Scissor Lift Table is a device that employs a scissors mechanism to loading and unloading (raise or lower) goods (like material from container or truck or any vehicle) and / or persons. Typically Lift Tables are used to raise large, heavy loads through relatively small distances. Common applications include pallet handling, vehicle loading and unloading work. Manual Scissor Table is used for die, tools, fixtures, etc. assembling / disassembling from the machine. ST is very useful product; you have direct access to it. You can directly keep material on it and move into or out of vehicle.

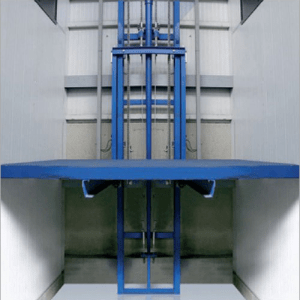

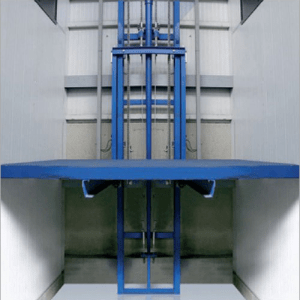

5. Industrial Goods Lifts

Goods Lifts (Industrial Goods Lifts), Hydraulic Goods Lifts, Electric / Hoist Operated Goods Lifts are used to lift goods vertically in a safe way.

These kinds of lifts require special safety measures. Goods Lifts are used for up and down movement of material in a factory or warehouse. It is used only for material or goods, not for lifting humans. You can lift Pallets or direct material from it. It is very helpful for customers to use vertical space.

6. MS Trolleys And Pallet

MS (Mild Steel) Trolleys, MS (Mild Steel) Platform Trolleys, MS (Mild Steel) Weld Mesh Trolleys, MS (Mild Steel) Tool Trolleys, MS (Mild Steel) Pallets, Sheet Metal Pallets, MS (Mild Steel) Pipe Pallets, Customized MS (Mild Steel) Pallets. The Platform Trolleys are made to handle material at ground level. With the vary capacity and material. Its construct from MS as well as SS. The MS Pallets are option to the wooden or plastic pallet. All are used for handling of raw material or a finished goods. These trolleys are also used in warehouse, shops, home, offices, hotels, etc. which help to do easy handling of material. MS pallet are option for plastic or wooden pallets. It is used for heavy weight material or if customized sizes. There are some products which you cannot keep on wooden or plastic pallets, in that case MS pallet is used. MS pallet are heavy, durable, and easy to handle. MS pallets can be handled by all material handling equipment’s.