Degassing Machines

Nonferrous foundries today require very stringent quality standards to prevent rejections and other failures in critical components of automobiles, airplanes, and machinery. Degassing systems use a very high-purity inert gas (Argon/ Nitrogen) to remove hydrogen from molten aluminum to improve metal quality. Inclusions can lead to increased porosity, loss of mechanical properties, poor surface finish, broken tools, lack of pressure tightness, and reduced corrosion resistance.

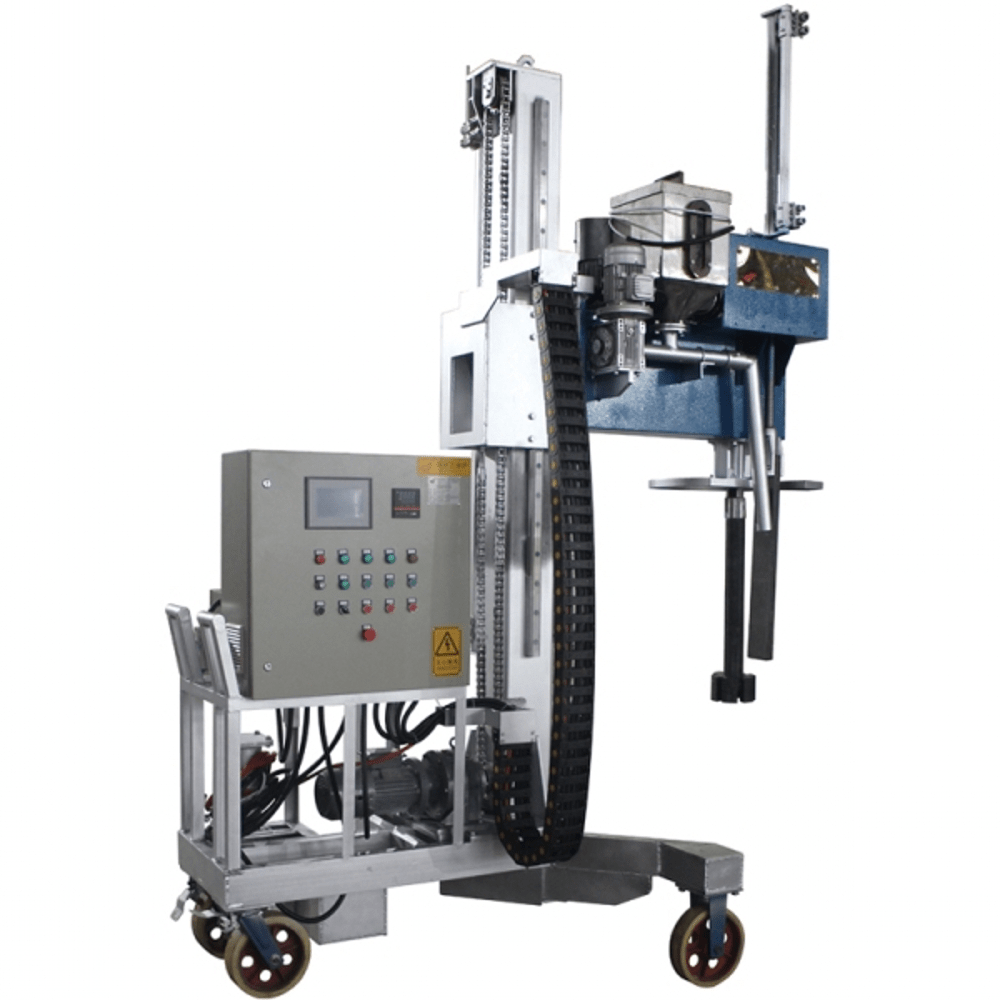

We offer the below-mentioned degassing systems:

- Fixed Type

- Moving Type

- Hoistable Type

All the above degassing machines come with an option of Inbuilt flux injection systems, fully automatic transverse, and PLC-controlled movement. The degassing cycle time depends on the application and can vary between 10 minutes to 30 minutes.

Kindly contact us for further assistance.